What is a Vial Filling Machine and How Does it Work in the Pharmaceutical Industry

Table of Contents

- Definition of Vial Filling Machine in the Pharmaceutical Industry

- Key Components of Vial Filling Machines

- Working Principles of Vial Filling Machines

- Types of Vial Filling Machines Used in Pharmaceuticals

- Automation and Technology in Vial Filling Processes

- Importance of Quality Control in Vial Filling Operations

- Applications of Vial Filling Machines in Drug Manufacturing

- FAQS

- Conclusion

- Related Posts

In today’s fast-changing world of pharmaceuticals, having reliable and precise packaging solutions is super important. One piece of equipment that really stands out in this industry is the Vial Filling Machine. It’s pretty much a game-changer—it automates filling vials with all sorts of liquid meds, helping to keep the quality consistent and lowering the chances of contamination. As pharmaceutical companies face the rising demand for injectable drugs, it’s crucial to understand how these machines work so that they can boost productivity and keep safety on point.

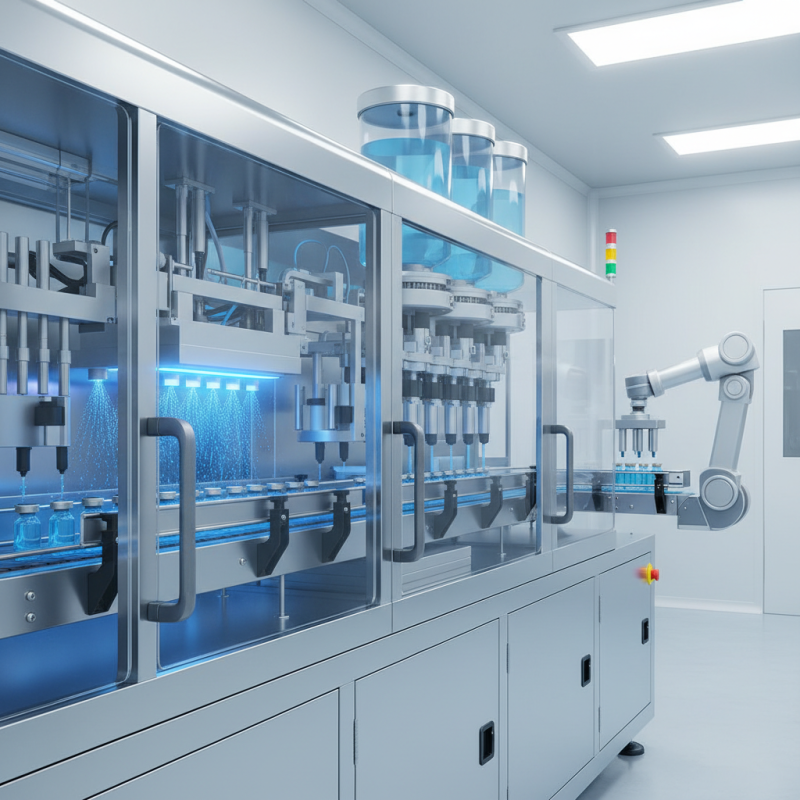

So, how does a Vial Filling Machine actually work? Well, it uses some pretty advanced tech—think of it as a smart system that measures and dispenses liquids into vials with a lot of accuracy. The whole process involves several steps: cleaning and sterilizing the vials, filling them up, and then capping them tight so nothing spills or gets contaminated. Modern machines often have things like programmable controllers and automated controls built in, which make sure everything runs smoothly and precisely. As we dig into the details of these machines, we’ll look at what makes them tick, how they operate, and why they’re so key to making sure medicines reach patients all around the world safely and effectively.

Definition of Vial Filling Machine in the Pharmaceutical Industry

A vial filling machine is a critical component in the pharmaceutical industry, designed specifically for the precise filling of vials with liquid formulations, powders, or suspensions. These machines automate the filling process, ensuring that each vial is filled to the correct volume while minimizing contamination risks. With the increasing demand for biopharmaceuticals and generic drugs, the global vial filling machine market is projected to grow significantly, reaching an estimated value of over $1 billion by 2025, according to a recent market research report.

The operation of a vial filling machine is mainly characterized by its ability to maintain sterile conditions throughout the filling process, which is crucial for ensuring product safety and efficacy. The machines typically employ various technologies, such as aseptic filling methods, which utilize laminar flow hoods and isolators. This ensures that the filling process adheres to stringent regulatory requirements set forth by health authorities. Additionally, the efficiency of these machines, often capable of filling hundreds of vials per minute, is vital in meeting the production demands of a rapidly growing pharmaceutical market, which is expected to expand by at least 7% annually through 2030.

Moreover, advancements in vial filling technology, including automated vision systems and robotics, are transforming the landscape of pharmaceutical manufacturing. These innovations enhance accuracy and reduce human error, further solidifying the role of vial filling machines as an essential tool in modern pharmaceutical production environments. As the industry continues to evolve, the importance of these machines in maintaining the integrity and safety of pharmaceutical products cannot be overstated.

Key Components of Vial Filling Machines

Vial filling machines are essential in the pharmaceutical industry, designed to automate the process of filling vials with liquid products, such as vaccines or injectable formulations. These machines consist of several key components that ensure accurate filling, safe handling, and efficient production. Understanding these components can provide insight into the operation and effectiveness of vial filling machines.

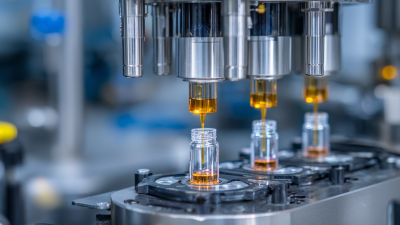

One of the primary components is the filling nozzle, which is responsible for delivering the liquid into the vials. These nozzles can vary in design, depending on the viscosity of the product being filled. Another vital part of the machine is the conveyor system, which moves vials through different stages of the filling process. This ensures a seamless workflow from the filling station to capping and labeling, minimizing the risk of contamination and maximizing productivity.

Additionally, the control systems play a crucial role in maintaining precision throughout the filling operation. They monitor parameters such as fill volume, speed, and pressure, making real-time adjustments to ensure consistency. The incorporation of sensors for detecting vial presence and alignment is also important, as it helps prevent errors that could lead to product wastage or contamination. Together, these components form a well-coordinated system that is critical for maintaining quality and efficiency in the pharmaceutical manufacturing process.

Working Principles of Vial Filling Machines

Vial filling machines play a critical role in the pharmaceutical industry, ensuring that liquids, powders, and gel products are accurately dispensed into vials for safe storage and distribution. The working principle of these machines revolves around a few key processes that ensure efficiency and precision. Initially, containers are aligned and securely held in place, often utilizing mechanisms such as conveyor belts or indexing systems. This alignment helps minimize the risk of spillage and contamination during the filling process.

Once the vials are properly positioned, the actual filling begins, which can be achieved through various methods such as gravity, vacuum, or piston filling. Automated systems typically control the quantity of product dispensed, ensuring uniformity and reducing human error. After filling, some machines may incorporate additional steps, such as capping or labeling, to streamline the production line. The use of sensors and feedback loops allows for real-time monitoring, significantly enhancing the accuracy and efficiency of the entire system while adhering to strict quality standards required in the pharmaceutical sector.

Vial Filling Machine Efficiency in Pharmaceutical Production

Types of Vial Filling Machines Used in Pharmaceuticals

In the pharmaceutical industry, vial filling machines are crucial for packaging liquid drugs, ensuring precise and sterile filling processes. There are several types of vial filling machines that cater to different production scales and requirements. The most common categories include semi-automatic and fully automatic filling machines.

Semi-automatic machines usually require manual intervention for tasks such as capping and labeling, making them suitable for smaller batches or facilities with limited budgets. According to a report by Grand View Research, the semi-automatic vial filling machine market is expected to reach approximately $1.2 billion by 2025, highlighting their ongoing relevance in the industry.

On the other hand, fully automatic vial filling machines are designed for large-scale production, implemented in high-volume manufacturing environments. These machines often integrate advanced technologies such as in-line filling and monitoring systems to ensure precision and maintain sterile conditions. A report by Research and Markets indicates that the fully automated segment is projected to grow significantly, expected to account for over 60% of the market share by 2024. Additionally, specialized machines like aseptic vial filling machines are designed to fill pharmaceuticals in aseptic environments, critical for sensitive biologics and injectables, further illustrating the diverse needs met by various vial filling technologies in the pharmaceutical sector.

Automation and Technology in Vial Filling Processes

The pharmaceutical industry has embraced automation and advanced technology to enhance the efficiency and accuracy of vial filling processes. A significant trend in this sector is the increasing adoption of automated vial filling machines, which are designed to minimize human intervention, reduce errors, and optimize production timelines. According to a report by MarketsandMarkets, the global automated vial filling machine market is expected to grow from $2.4 billion in 2021 to $4.1 billion by 2026, reflecting a compound annual growth rate (CAGR) of 11.3%. This growth is driven by the rising demand for biologics and aseptic manufacturing, necessitating high-precision filling equipment.

The integration of smart technologies, such as IoT (Internet of Things) and artificial intelligence (AI), into vial filling machines has further revolutionized the process. These technologies enable real-time monitoring and control of production parameters, enhancing the overall quality and consistency of the final product. For instance, Industry 4.0 initiatives have led to improvements in predictive maintenance and operational efficiency, resulting in reduced downtime and waste. According to a study published in the Journal of Pharmaceutical Sciences, the implementation of automation in vial filling lines can reduce filling errors by up to 90%, significantly improving compliance with regulatory standards and enhancing patient safety. These advancements underline the critical role that automation plays in modernizing pharmaceutical manufacturing processes, ensuring that products are delivered to market in a timely and reliable manner.

Importance of Quality Control in Vial Filling Operations

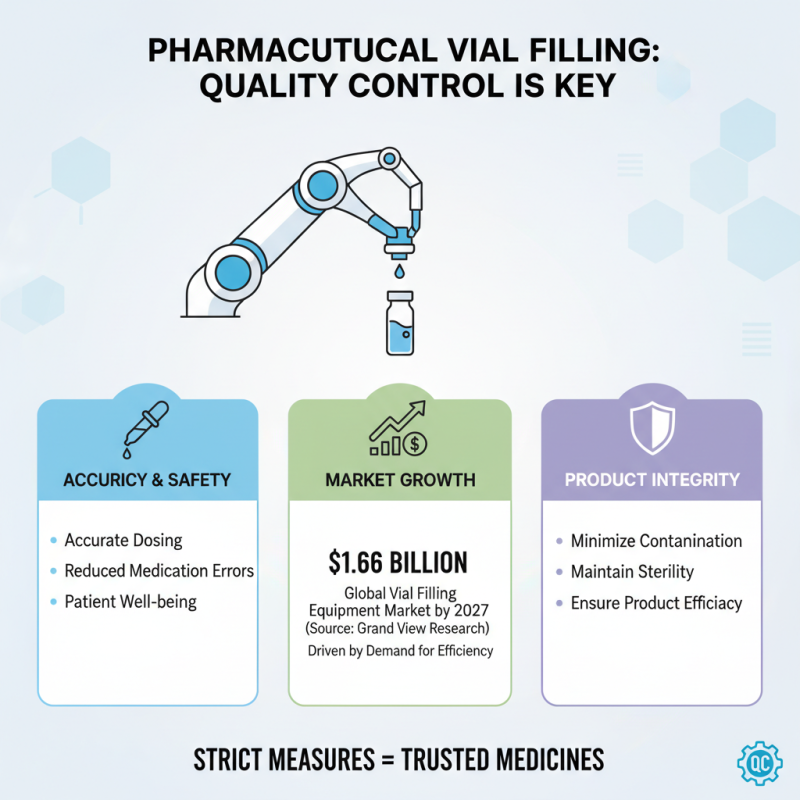

In the pharmaceutical industry, the importance of quality control in vial filling operations cannot be overstated. Vial filling machines are integral to the production process, ensuring that pharmaceutical products are dispensed accurately and safely into their containers. According to a report by Grand View Research, the global vial filling equipment market is expected to reach approximately $1.66 billion by 2027, reflecting the increased demand for efficiency and quality in drug manufacturing. As the industry evolves, stringent quality control measures are implemented to minimize contamination risks and ensure product integrity.

A critical aspect of quality control in vial filling is the validation of the filling process itself. This includes regular calibration of machines, monitoring fill volumes, and inspecting vials for any defects. The U.S. Food and Drug Administration (FDA) mandates that pharmaceutical companies adhere to strict guidelines, ensuring that less than 1% of products fail quality inspections. Additionally, advances in automation and machine learning have enabled manufacturers to enhance precision and reduce human error significantly. A study from the International Society for Pharmaceutical Engineering emphasizes that integrating real-time monitoring systems can lead to a 30% reduction in variability during the filling process, thereby improving the overall quality of pharmaceutical products.

Applications of Vial Filling Machines in Drug Manufacturing

Vial filling machines play a crucial role in the pharmaceutical industry, specifically in the manufacturing of injectable drugs. As the market for injectable formulations continues to expand, driven by the increasing prevalence of chronic diseases and the rise of biologics, the demand for efficient and precise vial filling solutions has intensified. According to industry reports, the global vial filling machine market is expected to reach $1.5 billion by 2025, growing at a CAGR of around 7% from 2020 to 2025. This growth underscores the importance of these machines in ensuring that pharmaceuticals are safely and effectively delivered to patients.

In drug manufacturing, vial filling machines are applied in both the aseptic and non-aseptic filling processes. Aseptic filling is particularly significant as it ensures that sterile drugs are packaged in a contamination-free environment, a critical requirement for injectable medications. The machines can handle various types of vials and formulations, including vaccines and monoclonal antibodies, which require exact volume measurements and precise filling operations. The automation of these machines aids in minimizing human error, enhancing productivity, and maintaining the integrity of the products.

Tips: When selecting a vial filling machine, it’s essential to consider the compatibility with the specific type of vial and drug formulation. Ensuring that the equipment adheres to stringent regulatory standards can also prevent potential quality issues. Moreover, regular maintenance and calibration of the machines are crucial for sustaining optimal performance and accuracy in the long term.

What is a Vial Filling Machine and How Does it Work in the Pharmaceutical Industry - Applications of Vial Filling Machines in Drug Manufacturing

| Dimension | Description |

|---|---|

| Filling Speed | Typically ranges from 50 to 400 vials per minute, depending on the machine type. |

| Filling Volume | Can accommodate a range of volumes from 0.5 mL to 100 mL. |

| Types of Vials | Can fill glass and plastic vials, with sizes varying from small to large capacities. |

| Automation Level | Available as manual, semi-automated, or fully automated systems. |

| Cleanroom Compatibility | Designed to operate in cleanroom environments to maintain sterile conditions. |

| Control System | Equipped with PLC or touchscreen controls for ease of operation and monitoring. |

| Applications | Used for aseptic filling of injections, vaccines, and biopharmaceutical products. |

| Regulatory Compliance | Must comply with FDA, EMA, and other regulatory standards for pharmaceutical manufacturing. |

FAQS

: The most common types of vial filling machines include semi-automatic and fully automatic machines, with specialized options like aseptic vial filling machines also available for sensitive products.

Semi-automatic machines are suitable for smaller batches or facilities with limited budgets, as they require manual intervention for tasks such as capping and labeling.

Fully automatic machines are designed for large-scale production, integrating advanced technologies for precision and sterility, making them ideal for high-volume manufacturing environments.

Automation enhances efficiency, minimizes human intervention, reduces errors, and optimizes production timelines, significantly improving compliance with regulatory standards.

These technologies enable real-time monitoring and control of production parameters, improving quality, consistency, and operational efficiency in the filling process.

Quality control is crucial to ensure accurate and safe dispensing of pharmaceuticals, with strict guidelines in place to minimize contamination risks and ensure product integrity.

Regular calibration of machines, monitoring fill volumes, and inspecting vials for defects are essential quality control measures to maintain high standards in production.

The global automated vial filling machine market is projected to grow from $2.4 billion in 2021 to $4.1 billion by 2026, reflecting a compound annual growth rate (CAGR) of 11.3%.

Implementing real-time monitoring systems can lead to a 30% reduction in variability during the filling process, enhancing overall product quality.

Regulatory standards, such as those mandated by the FDA, require pharmaceutical companies to ensure less than 1% of products fail quality inspections, driving the need for stringent quality control measures.

Conclusion

A Vial Filling Machine is a crucial piece of equipment in the pharmaceutical industry, designed to automatically fill vials with various liquid formulations. These machines are composed of key components including filling nozzles, conveyors, and capping devices, all working in unison to ensure efficient and accurate filling. The functioning of a Vial Filling Machine involves several principles, such as precise volume control and sterile handling, which are essential in maintaining the integrity of pharmaceutical products.

There are various types of Vial Filling Machines employed in drug manufacturing, ranging from semi-automatic to fully automatic systems, each tailored to meet specific production needs. Automation and advanced technology play significant roles in optimizing the vial filling process, enhancing efficiency, and minimizing human error. Moreover, stringent quality control measures are vital in these operations to ensure compliance with health regulations and to guarantee product safety. Overall, Vial Filling Machines are integral to the reliable and safe manufacture of pharmaceuticals, with applications extending across a wide range of drug formulations.

Related Posts

-

10 Essential Tips for Choosing the Right Vial Filling Machine

-

Revolutionizing Pharmaceutical Production with Advanced Vial And Ampoule Filling Machine Technology

-

How Vial Filling Machines Revolutionize the Pharmaceutical Industry: A Closer Look

-

2025 Top 5 Vial Filling Machines: Boost Your Production Efficiency Today!

-

What is Efficient Blister Production and How It Transforms Pharmaceutical Packaging

-

Ultimate Checklist for Choosing the Best Capsule Filling Machine in China

Blog Tags: